Universal NAND gate and its application in level monitoring in chemical plant

1 INTRODUCTION

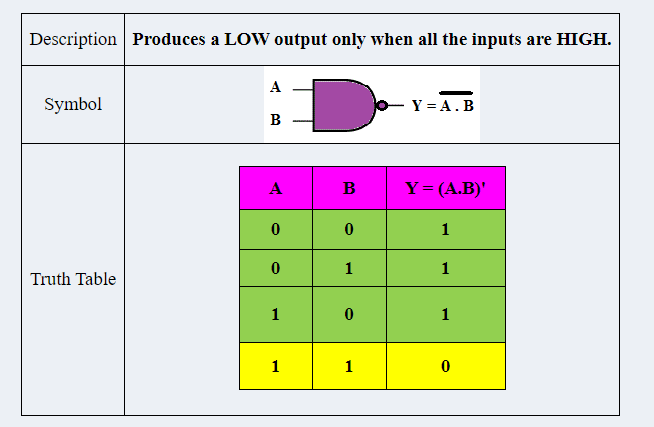

The NAND operation is the complement of AND operation and is defined by Y = (A.B)'. The NAND operation is also called the Sheffer stroke named after Henry M Sheffer. The NAND gate is a NOT-AND, or an INVERTED AND function. A NAND gate is also referred to as universal gate because any basic logic function can be derived from NAND gate. The utility of the NAND gate is explored by using NAND gate in level monitoring application.

1.1 NAND GATE

1.2 APPLICATION: LEVEL MONITORING IN A CHEMICAL PLANT.

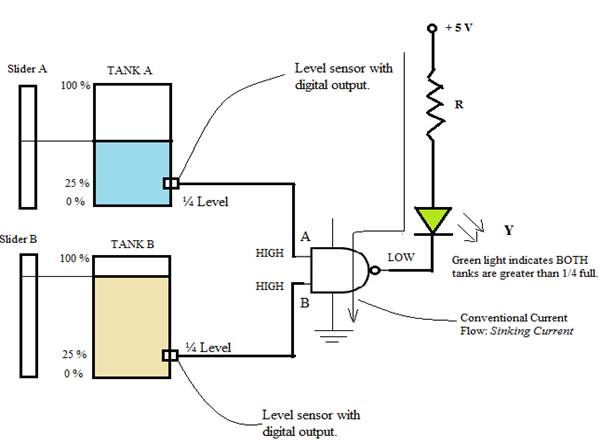

Consider the example of a level monitoring system that uses two tanks to store a certain liquid chemical that is required in a manufacturing process. The requirement is to display that both the tanks are well above the reserve/set level.

1.3 CONCEPT: The behaviour of NAND gate that it produces a LOW output only when all the inputs are HIGH can be fully explored. NAND gate can be used to indicate green light ON as long as both tanks are sufficiently filled (more than 1/4 full).

Each tank has a digital-output sensor that detects when the chemical level drops to 25 % of full. The sensors produce a + 5 V level when the tanks are more than 1/4 full. When the volume of chemical in a tank drops to 1/4 level (one-quarter full), the sensor puts out a 0 V level. The tank level sensors are interfaced to the two inputs of NAND gate. Green LED turns ON when both tanks are more than one-quarter full.

As long as "both sensor" outputs are HIGH (+5 V), indicating that both tanks are more than 25 % of full, the NAND gate output is LOW (0 V). The green LED is arranged so that a LOW voltage at the NAND output turns it ON i.e. If tank A AND tank B are above one-quarter full, the LED glows and emits green light. In this arrangement, we refer the IC as 'sinking' the current.

Current Sinking: The sinking current appears to start with + 5 V above the external circuit ( limiting resistor & LED) and "sink" to ground through the output pin of the NAND gate.